Countersinking Spar Rivet Holes January 21st, 2008

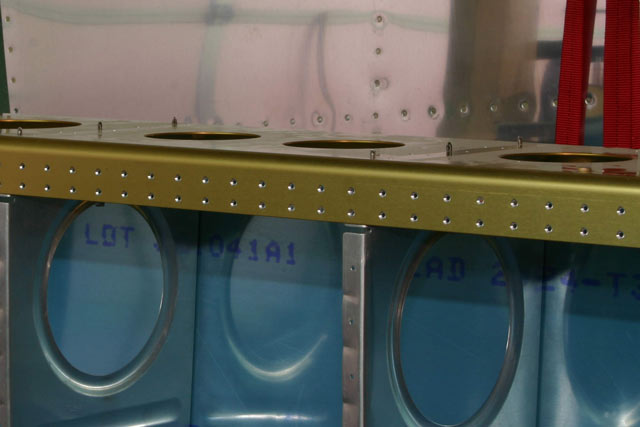

Before fitting the leading edge again for final assembly, I countersunk all the holes where the leading edge attaches to the spar. The construction manual doesn’t really talk about this, but the leading edge skin holes have already been dimpled, so in order for things to fit tightly, these holes need to be countersunk (the spar is too thick to be dimpled!!!)

The task is very straightforward — just set the correct countersink depth and start drilling. The only thing to be aware of is that the countersink depth will change slightly depending on how hard you push, and may even drift just a tiny bit over time. I used a rivet to check for the correct depth every four rivets or so.

There are 65 holes on each side of each spar, so that’s total of 260 holes, just for the leading edge. There are a few hundred more where the main skin attaches 🙂