Shrinking a Hole (cont…) April 11th, 2007

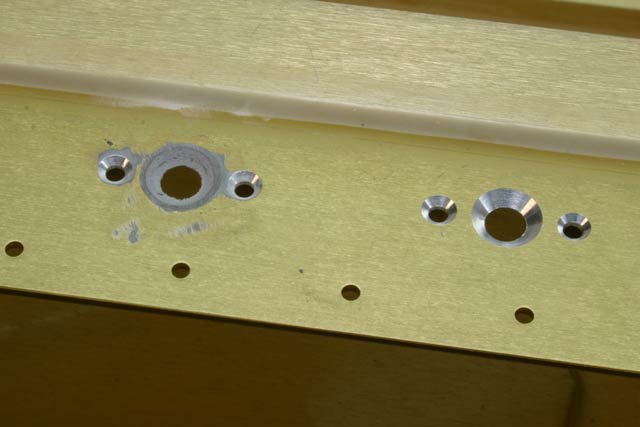

After leaving the JB Weld alone for a couple of days, I figured it was about as dry as it would get. I first used my Scotch Brite wheel on my air grinder to polish the epoxy so it is flush with the spar flange. This stuff is pretty easy to take off, so I had to go slowly and carefully. I manged to not expose too much more bare aluminum along the way.

Then I used my handy aluminum angle guide to drill a another hole. As you can see in the picture below, I had to cut off some of the angle to allow the 90 degree drill to fit perpendicular to the flange. I got this drill from Brown Tools on a sale. I’ve only used it two or three times, but it’s already paid for itself.

Finally, I countersunk it again, being careful to not go too deep this time.

Doesn’t look as shiny as the original, but it actually looks pretty good, considering….

Now on to more interesting stuff….