More Front Spar Work February 26th, 2006

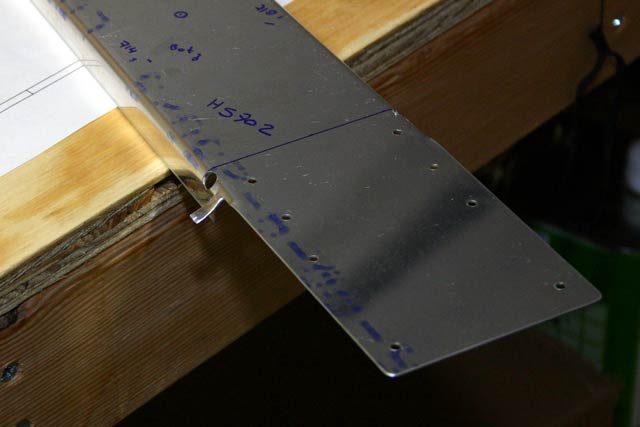

After preparing the reinforcement angles, the spar channel itself has to be bent as well. The spar is also used in the RV8, so it needs to be trimmed for the RV7. The trimming consists of removing a small amount of flange on each side of the channel.

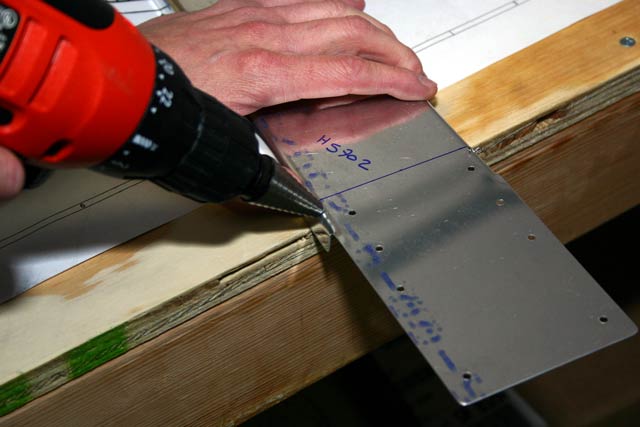

To avoid creating stress points, I first drilled a #30 hole where the flange would be removed. I then enlarged the hole with a unibit so that the edge of the hole coincides with the location where the flange is to be cut off.

I then used sheet metal shears to cut off the flange. Rather than remove all the material in one cut, I removed a little at a time. This is a trick I learned when I first met with my EAA tech advisor. Instead of having the flange deform as I cut it, the small piece deforms, and the ‘good’ side of the material remains nice and straight.

Finally, I used this little tip (see below) on the dremel tool to smooth out the edge a bit. I’ve found this tip very useful for quickly removing small amounts of material.

Finally, I used a Scotch-Brite wheel to polish the edges so no sharp points remain.